01.

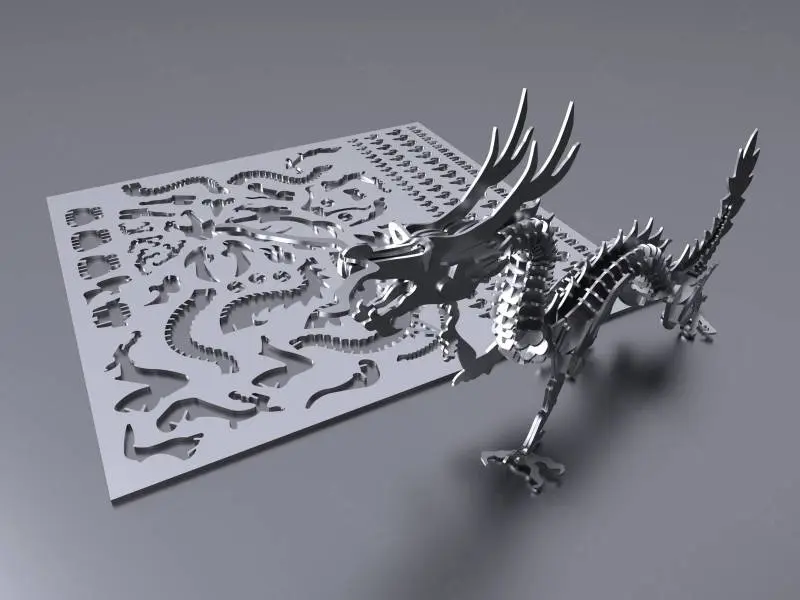

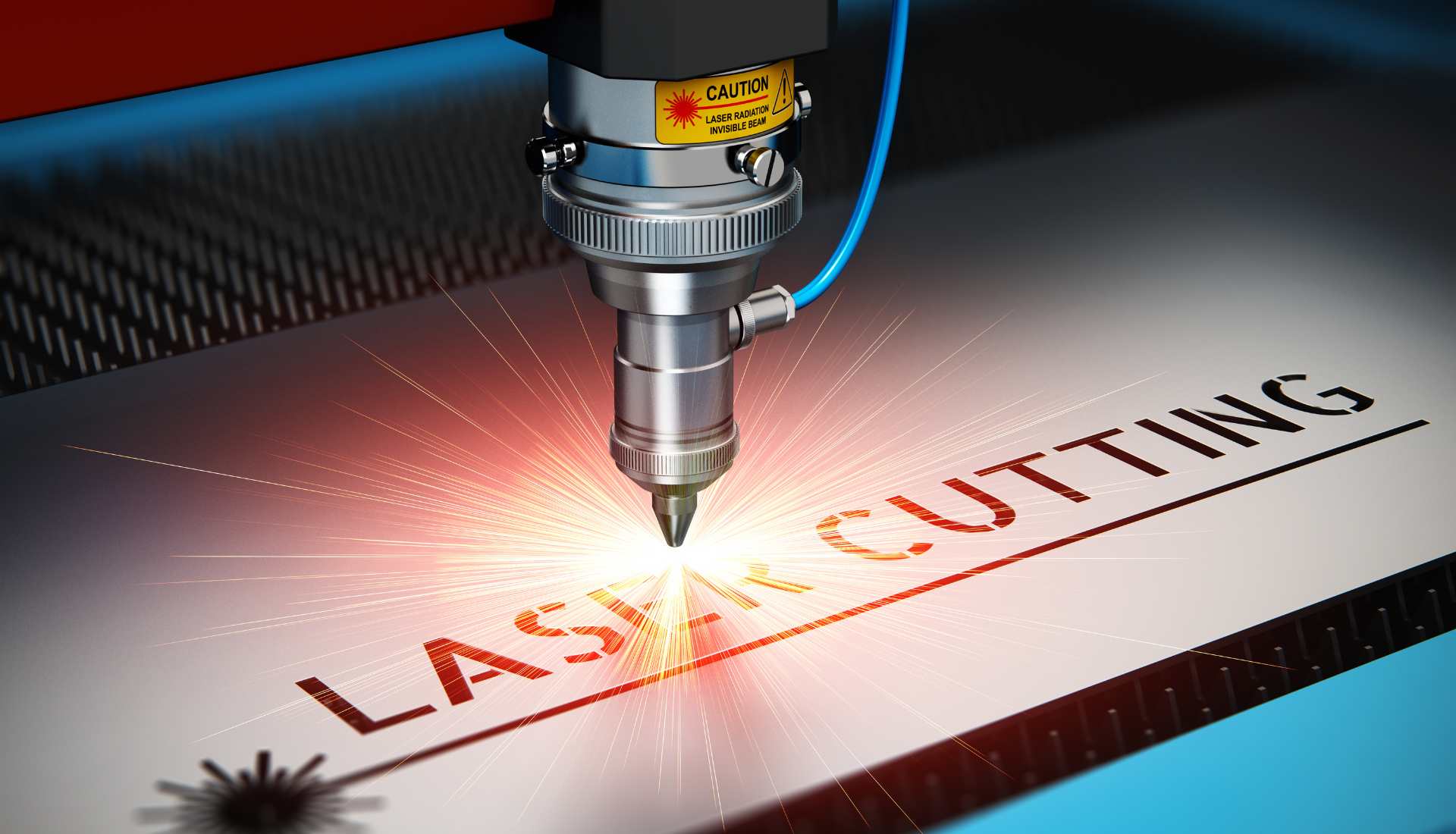

Precision and AccuracyLaser cutting offers exceptional precision and accuracy, making it an ideal choice for cutting intricate and detailed designs. The focused laser beam can create fine cuts with minimal heat-affected zones, ensuring that the final product matches the intended specifications.

02.

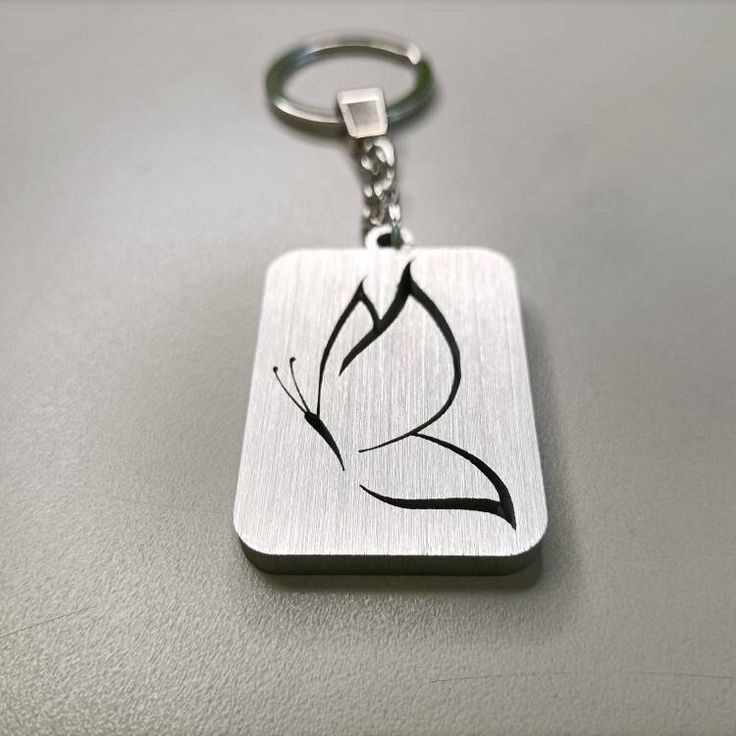

Versatility in Material CompatibilityLaser cutting can be used on a wide range of materials, including metals, plastics, wood, fabrics, and more. This versatility allows for the creation of a diverse array of products, from custom metal parts for industrial machinery to delicate laser-cut paper or acrylic designs for artistic or promotional purposes

03.

Minimal Post-Processing RequiredLaser cutting often requires minimal post-processing, reducing the need for additional finishing steps. This efficiency not only saves time but also minimizes material waste, making it a cost-effective manufacturing method for producing high-quality products.

We are delivering AI based powerful technology

AI-based laser cutting technology can adapt in real-time to varying material properties and environmental conditions. It intelligently optimizes cutting parameters, ensuring consistent results, even when dealing with different materials or complex geometries.

AI can monitor the health of laser cutting systems and predict when maintenance is needed. By proactively addressing issues, it minimizes downtime, reduces operational costs, and extends the lifespan of the equipment.

AI algorithms can analyze intricate designs and automatically generate cutting paths that minimize waste and enhance efficiency. This enables the production of intricate, customized products with minimal material usage.

AI technology can implement real-time quality control, detecting and correcting defects during the cutting process. It ensures that the final product meets stringent quality standards, reducing the need for post-production inspection and rework.

4650

Happy Clients3790

Project Completed5580

Photo Capture8580

Telephonic Talk

Wanna deal with us? Fill the contact form and just relax. Our expert will call you shortly.